Table of Contents

Introduction

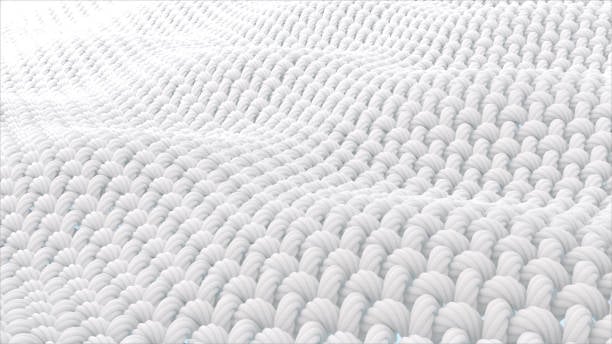

Woven cotton fabric is one of the most versatile and widely used fabrics in the world. It is used in various industries, including fashion, home decor, and manufacturing. In this article, we will explore the fascinating process of how woven cotton fabric is made, from the cultivation of cotton plants to the final weaving process.

Growing and Harvesting Cotton

The journey of woven cotton fabric begins with the cultivation and harvesting of cotton plants. Cotton plants are grown in warm climates, where they require ample sunlight and water. Once the cotton bolls are fully matured, they are picked by hand or with machinery. The harvested cotton is then processed to remove impurities, such as seeds and leaves, through a process called ginning.

Preparation of Cotton Fibers

After ginning, the cotton fibers are separated from the seeds. The fibers are then cleaned and straightened to prepare them for spinning. This process involves passing the cotton through various machines that remove any remaining impurities and align the fibers in a parallel arrangement. The cleaned and carded cotton is then ready for the spinning process.

Spinning the Cotton

Spinning is the process of transforming the cotton fibers into yarn. There are two main methods of spinning used in the textile industry: ring spinning and open-end spinning. In ring spinning, the fibers are drawn out and twisted using a spinning frame, resulting in a fine and strong yarn. Open-end spinning, on the other hand, involves spinning the fibers using a rotor, which produces a coarser yarn.

Dyeing the Yarn

Once the cotton fibers have been spun into yarn, they can be dyed to achieve the desired color. Dyeing can be done at various stages of the manufacturing process, but it is commonly done after spinning. The yarn is immersed in dye baths, where it absorbs the dye to achieve the desired hue. Different dyeing techniques, such as vat dyeing and reactive dyeing, can be used to create a wide range of colors and patterns.

Preparing the Loom

The next step in the production of woven cotton fabric is preparing the loom. A loom is a device used to weave the yarn into fabric. Before weaving can begin, the loom needs to be set up and prepared. This involves threading the yarn through the loom's heddles and reed, as well as adjusting the tension to ensure proper weaving.

Weaving the Fabric

Now comes the most crucial step in the process: weaving the fabric. The prepared loom allows the weaver to interlace the yarns, creating the structure of the fabric. The two main types of weaving used for cotton fabric are plain weave and twill weave. In plain weave, the weft yarn passes over and under each warp yarn alternately. Twill weave, on the other hand, creates a diagonal pattern by passing the weft yarn over several warp yarns before going under.

Finishing the Fabric

After the fabric is woven, it undergoes a series of finishing processes to enhance its appearance and properties. These processes may include washing, bleaching, and softening. Washing removes any remaining impurities and sizing agents, while bleaching is done to achieve a pure white color. Softening makes the fabric more comfortable and gives it a softer feel.

Inspection and Quality Control

Before the woven cotton fabric can be packaged and distributed, it goes through a rigorous inspection and quality control process. Textile experts examine the fabric for any defects, such as weaving errors or flaws in the dyeing process. Only fabrics that meet the industry's quality standards are approved for further processing and distribution.

Final Thoughts

Woven cotton fabric is a result of a complex and intricate manufacturing process. From the cultivation of cotton plants to the weaving of fabric, every step requires precision and expertise. Understanding how woven cotton fabric is made not only gives us a newfound appreciation for this versatile material but also allows us to make informed choices when selecting and using cotton fabric in our everyday lives.